Master planning is an essential part of asset management for colleges and universities, as well as major industries and institutions, that have planned growth in their vision statements. To continue progressing in their ventures — whether that's providing education, health care, etc. — or to simply increase corporate profits, an organization should have a master plan that will be monitored and measured annually. Plus, this master plan should be updated after sustained substantial growth or success. Otherwise, most organizations set a timeline to revisit their master plan progress and determine a possible future master plan update (i.e., every two, three, four, or five years, etc.).

Master plan sections and subsections

The primary sections of a master plan for an institution will be focused on the core business. For example, at a college or university, sections would include areas of study, such as political science, engineering, literature, etc. Levels of education would be included too, such as associate, bachelor’s, master’s, and doctoral degrees.

As a minimum, subsections, or appendices to the master plan, would include support services, like HVAC utility infrastructure as well as all other associated infrastructure. These sub-sections may be presented as their own standalone master plan documents.

What drives the need to have a master plan for the primary sections that address the core business with its goals and objectives? Some examples of past drivers are listed below.

- The business plan for companies, such as industrial, pharmaceutical, etc., addressing the products provided and future opportunities. For academia, their current and future educational vision and mission plans. For medical institutions, this would be their commitment to providing health care to the community and research and development to keep pace with the future.

- Future growth, whether as one entity or sub-departments that make up the core business (e.g., departments, educational degrees, etc.).

- Future growth and impact on real estate, the business core community, and adjacent community.

- Profit centers and the assessment of existing profit centers.

- Reorganization, elimination, and/or expansion of profit centers.

Today, there are additional drivers to be included in many master plans that address the environment, both locally and globally. Some examples of these include the following.

- Building occupant health, as well as space comfort and energy conservation.

- Occupant quest that the organization commit itself to solving global warming by reducing the real estate’s carbon footprint.

- The goal of achieving net zero carbon footprint on the organization’s present building/campus landscape through decarbonization.

- Electrification and the elimination of fossils fuels serving the complex.

HVAC support services would have its own utility infrastructure subsection master plan that will be discussed in next month’s issue of Engineered Systems. Before that discussion comes the need to outline the process of completing a utility infrastructure assessment, using the HVAC subsection report/document and recognizing there are two types of HVAC master plans.

- The initial report, in sync with the primary master plan, indicates the current infrastructure, operating conditions, issues and concerns, and recommendations to maintain and/or achieve system performance to accommodate the primary master plan.

- The second report is to update an existing subsection master plan report, including timelines and costs, based on accommodating existing and new objectives set in the primary master plan.

The second scenario would be to program a master plan update every five to 10 years based on the institution or organization and include:

- Anticipated growth of the complex or campus.

- Utility deferred maintenance master plan (to be discussed herein).

- Global issues and current concerns.

- To a lesser degree, issues and concerns with neighboring facilities.

- Recent building additions, and/or remote facility impact on the HVAC support services.

When submitting the company’s proposal to complete a master plan, whether requested or not, it is suggested the firm include an add-on proposal to label each piece of equipment with a bar code designation that could be included in the final asset database spreadsheet. This will be way more cost-effective than surveying and barcoding HVAC equipment in the future.

A second add-on would be to provide video of each equipment room to verify the space is adequately lit ad=nd safety measures are in place. They say a picture's worth a thousand words — imagine how much a video could be worth.

Plan to profit

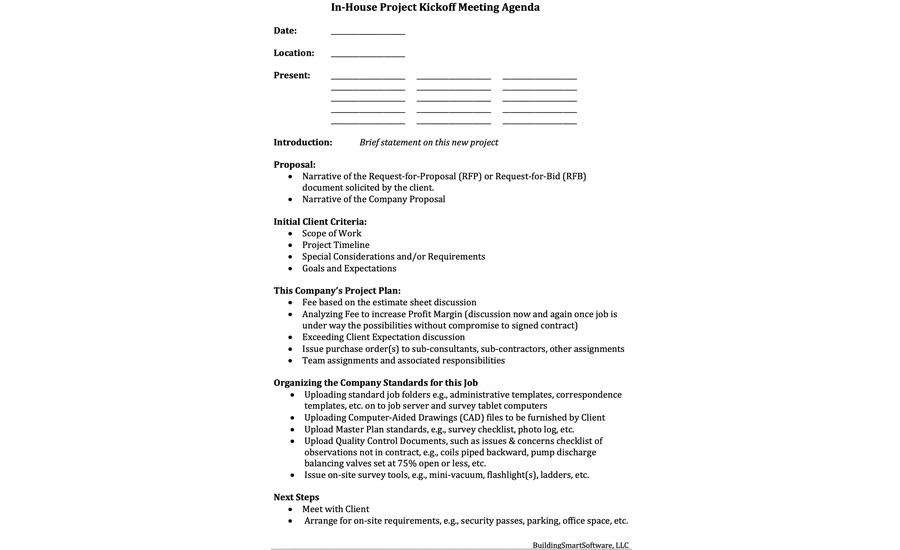

With authorization to proceed, the master plan team (MPT) should begin the process with a kickoff meeting to discuss the following:

- Project job authorization scope of work.

- Planning to make a profit.

- Organizing the survey, documentation, evaluation, and report teams standard forms and checklists.

- HVAC system and equipment inventory.

Often this conversation fails to happen until it’s too late. Efficient project management begins with the receipt of the client’s authorization-to-proceed document and the MPT’s in-house kickoff meeting.

Communication is critical to project success, and, when it comes to providing a quality master plan report, it should include making a profit too. The assumption should never be that "delivering a quality report will provide the potential for more work from the client.”

The next step should be to organize the survey, documentation, evaluation, and report teams procedures. This also means making sure each team member is familiar with the documents and how to complete them — for example, each primary and secondary piece of equipment shall have a photograph attached to the equipment survey checklist. An example of the survey checklists may include the following primary and secondary equipment inventory:

- Heating system

- Central plant equipment (heat changers, pumps, etc.)

- Decentralized mechanical room equipment and rooftop equipment

- Air-conditioning system(s)

- Central plant equipment (refrigerant units, pumps, etc.)

- Decentralized mechanical room equipment and rooftop equipment

- Associated heat rejection equipment (cooling towers, condensers, etc.)

- Ventilation system(s)

- Fan rooms (outdoor air-handling units, energy recovery units, etc.)

- Special systems and equipment inventory

- Self-contained units (computer room air conditioning [CRAC] units)

- Engineered systems (smoke exhaust fans, etc.)

HVAC systems and terminal equipment inventory:

- Air terminals (variable air volume [VAV], etc.)

- In-Room terminals (fan coil units, unit ventilators, etc.)

The team

With an eye toward expediting the work, the MPT will usually consist of the following team members:

- Project manager to manage the process, maintain the project schedule, maintain meeting minutes and weekly or biweekly progress reports, and interact with the client’s team.

- The surveyor team(s) should include a lead individual with HVAC design engineering experience and a second person to fill in the system and equipment checklists.

- Data input person(s) collecting the completed survey checklist and recording all data collection in a master spreadsheet.

- Administrative assistant (not on-site) assisting the project manager and other team members as needed

- Accountant, (in the office), to provide financial project data, project financial status, and billing invoices

Note: The second surveyor, as well as the data input person could be a vocational school student or a college student from their co-op curriculum.

Additional team members, based on the scope of work may be:

- Estimator (not on site full time) who will assist the project manager in completing the master plan report if required as part of the project contract, e.g., facility condition indexing (FCI*) on a building-by-building estimate

- Sub-consultants and/or sub-contractors, e.g., non-destructive testing of a campus pipe distribution system, etc.

*The FCI published by the National Association of College and University Business Officers (NACUBO) as a practitioner’s method to benchmark comparison between its numerical scale and the perceived existing condition of a building and its infrastructure.

Quality Control: Don’t Jump to the Solution

To include quality control (QC) methods to the development of a master plan, one will find that the individuals responsible for producing the HVAC infrastructure master plan should not simple “jump to the solution” based on their years of experience. Consultants, who have experience with creating infrastructure master plans, may proceed with confidence based on this experience. But QC experience directs one to first, give the task a theme, e.g., “What is needed to provide a thorough HVAC infrastructure master plan?”

The steps to the answer to this question are as follows:

- Data collection

- Data analysis

- Solution options

- Solution implementation

Sure, one or two of the master plan contributors may have the solutions already for the MPT to move forward, believing to be the optimum approach to producing the master plan but, will it be as thorough as it should be? The answer is probably, No.

Why data collection, leading to analysis and planning? There is a saying, “Sometimes the obvious isn’t obvious” and without a comprehensive data collection of the facts, the proposed master plan may result in a less than acceptable for the building owner or organization to invest in moving forward. Analogous to purchasing a used automobile sight unseen, without a thorough inspection of this car, the new owner may fine he or she invested in a vehicle that’s engine needs to be replaced, the brakes are almost ready to be replaced, etc.

The process and tools

Data collection, which will be discussed in "HVAC master plan road map: Part 2" is essential to identifying all that is needed to know about the HVAC infrastructure, such as:

- Primary equipment (boilers, refrigeration units, and cooling towers) complying with its “design intent” document, e.g., 45F-to-55F chilled water delta-T compliance, physical condition of the equipment, estimated remaining useful service life, etc. The same applies to secondary equipment survey data collection.

Solution: Review operating records and, if inadequate information, begin to collect additional trending and other data that will allow the MPT to complete their data analysis leading to solution plan options. - For primary-secondary and primary-secondary-tertiary pumping systems, serving multiple buildings, consideration should be given to completing a hydraulic model of system to ensure efficient performance and achieve maximum pump horsepower efficiency.

Solution: recommend a hydraulic model of the system be completed as an add-on scope-of-work.(refer to Engineered Magazine February 2005, The Very Model of a Model Major Campus) - Review of record drawings and operation records including:

a. Record drawings of all HVAC constructions, renovation, and alterations

b. Review of past TAB reports, commissioning, retro-commissioning, and re-commissioning reports, as well as other pertinent studies, e.g., energy conservation recommendations

c. Priority equipment logs and past trending logs

Tools to be provided to each survey team, as a minimum may be as follows:

- Survey calendar designating the rooms scheduled to be inspected

- Room access keys

- Tablet computer with architectural room floor plans and HVAC record drawings to assist in checking off each room and equipment surveyed

- An 8-foot ladder

- Small hand vacuum with charger to clean the area e.g., after a ceiling tile has been reinstalled

- High powered flashlight

- Safety glasses

- Two-way radio or one’s cellphone for communication

- Cellphone camera to capture existing equipment conditions, as well as other concerns associated with the equipment. Note, any concerns would be noted on the specific survey sheet, e.g., possible safety concern

- Standardized spreadsheets to inventory the equipment, e.g., Excel or another spreadsheet app

- Equipment room safety checklist with video an additional option

- Photo log to be managed in sync with each piece of equipment survey sheet

The survey is ready

With in-house kickoff meeting complete, scope-of-work defined via the authorization-to-proceed, the MPT established, job responsibilities defined, and necessary survey tools in place, the team moves on to the site to begin the data collection and document existing conditions. It is suggested that future meetings be held on-site so that difficult questions needing to be reviewed further, then certain MPT members can simply walk to the equipment and area in question where answers can be made.

During the data collection phase, it is important to note whether the building(s) is under a negative pressure that would lead to the suggestion the facility is not in compliance with the design intent document. This observation would be a footnote in the report recommending the air systems, serving the build should be re-balanced to improve energy efficiency performance and improve indoor air quality.

Noted above, the preparation for this initial HVAC infrastructure master plan, or the updating of a previous master plan, will require a clear understanding of the future of existing buildings and the addition of new buildings to the site. With this knowledge, additional assessment(s) and action plans may be required should net zero carbon footprint, decarbonization and electrification feasibility be goals for the building owner. These studies and report recommendations could be added as a supplement of appendix to the final infrastructure master plan report.

Next month’s "HVAC master plan road map: Part 2 — completion and submission will take the reader through the second half of the infrastructure master plan.