Health care and technology are two mission critical priorities in today’s world. While health care is more often viewed as a life and death issue, society’s increasing digital dependence has turned technology into much more than a convenience. At the same time, seemingly insignificant issues, such as corrosion and scale, can seriously interfere with mission critical operations at hospitals and data centers if left unchecked. The following basic guidelines serve as small but important steps to include in an overarching maintenance plan for mission readiness.

Keep the hospital lights on

Many hospitals have their own plants that provide power, heating, and cooling to support operation 24/7. In addition to the simple needs of keeping the lights on and the rooms comfortable, hospitals must have a continuous power supply. Therefore, it’s mission critical to have backup systems and spares at the ready should main systems fail or need repair or maintenance. Corrosion in these backup systems may render them unavailable for immediate use or lead to malfunctions and a shorter service life. Preventing corrosion as part of routine maintenance can smooth the transition between primary and backup systems when an emergency or routine maintenance outage happens.

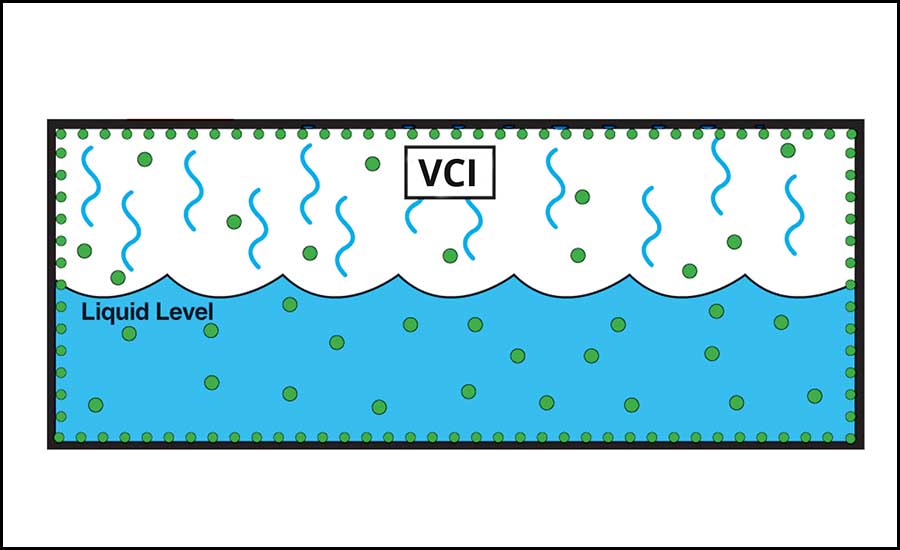

Boilers are used to generate steam for power production, heating, or other hospital activities. While corrosion and scale inhibitors are an indispensable part of the normal operating water treatment program, corrosion inhibitors should also be added to boilers on standby to avoid metal loss, clogging, and upsets to the water chemistry. Treatments with a vapor-phase component provide more comprehensive protection because they work below and above the water level. Vapor corrosion inhibitors (VCIs) also tend to be easier to work with than traditional methods of corrosion protection, such as monitoring sulfates and maintaining high pH levels in standby boilers. Similar vapor-phase chemistries can be used to protect cooling systems in operation and layup as well, so they can function longer without corrosion interruptions.

VCIs are also good for protecting spare valves, pumps, turbines, or other components that are stored for emergency replacement. VCIs form a protective molecular layer on metal surfaces within an enclosure but typically require little to no cleaning before the protected item can be used, allowing for speedy startup. Application methods vary, including packaging components in VCI film or fogging a VCI fluid into voids and covering all openings. Breathable pouches containing VCIs can be placed in generator housings — both operational and backup — and control panels to minimize corrosion damage and the amount of downtime otherwise needed for repair and/or replacement.

Keeping data centers cool

Similar methods can be used at data centers, which seem to be exploding in number. As more data is created, more storage space is needed to keep up with the demand. These data centers contain servers that generate excessive heat and need to be cooled down. However, scale and corrosion can hinder these cooling loops from “keeping their cool.” For example, scale buildup reduces heat transfer efficiency and can force a system to use more power to achieve the same level of cooling as a scale-free system. Scale also slows down flow rates, as do corrosion products that sometimes accumulate after seasonal layup. Scale and corrosion inhibitors should both be added to the cooling water treatment program to reduce these problems during operation. Scale removal should also be done during routine maintenance outages every few years or when there is a noticeable decrease in flow or heat transfer efficiency. Furthermore, facilities that save energy by turning off their cooling systems in the winter should ensure proper layup by using VCIs to inhibit corrosion inside the cooling loop while it is idle. Otherwise, workers may face issues with high iron levels and clogging of corrosion products.

Stay mission ready

Hospitals and data centers need reliable power and HVAC systems in order to function. While corrosion and scale may seem like small issues to start with, they can grow into serious problems if allowed to continue. By making corrosion and scale mitigation part of the normal maintenance and operating plan, hospitals and data centers can take an important step toward keeping the lights on, keeping their cool, and staying mission ready.